The goal of this project was originally to put in a tighter feeling IEC inlet than originally provided. The lack of a ground pin really leaves one with the feeling that your power plug is not gripping as well as it should be, and indeed, with heavy power cords it was unusually hard to keep a solid AC connection.

The simple goal morphed into making more modifications:

- New quick disconnect IEC C16 inlet replacing hard soldered C18

- 2x 0.01uF bypass caps replaced by single 0.022uF

- Wiring upgraded from 20 to 14 gauge as much as possible.

- Ensure the black wire was actually connected to the line input, so a blown fuse would disconnect the line and not the neutral. Not sure if this is a problem to Luxman amps that is unique to the US.

I found out three things I wish I had not known:

- Wiring from main transformer to inlet is 20 gauge

- The wrong wire was fused, at least for the US

- The main fuse is 15A, very high for an amp rated for 350 Watts using 20 gauge inlet wiring.

After re-assembly I can say that the new IEC connector feels somewhat better than the original in terms of grip confidence, and flipping which wire was fused is a long term safety issue that I'm glad I found, but may have never noticed. I'll post more if I find the increased wire thickness actually improved sound quality.

A new bypass cap was needed because the entire original inlet assembly had to be removed and was not easily reused without a wave solder machine. Plus, now I had an excuse to use far thicker power cables.

The original 2x 0.01uF X2 (safety) caps were replaced by a single yellow 0.022uF connected at the input crimp connectors. The inlet ground pin is left disconnected, but shrink wrapped out of an abundance of caution.

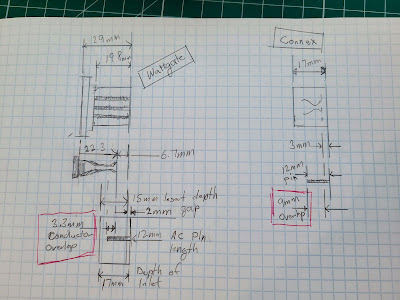

On the top left you can see the black and white wires next to the fuses. On the bottom right you can see the new inlet with the blue quick disconnect pins attached along with the decoupling capacitor.

The end of the power cables is the limiting factor. It appears to be a Molex Spox connector which I believe is limited to 18 gauge only. Even if I had the $700 Molex crimper I'd not be able to do much about the wire gauge anyway. If I had a thousand hours of course the solution is to remove the entire Molex connector and replace with something capable of handling a 14 gauge wire.

Here you can see a close up of the inlet section:

Effort Level

For some silly reason I had hoped this would be a 15 minute project. I'd unscrew the inlet, pull it out and replace it, shove it back into my rack. No, nothing like that. At the end of the day I needed to remove the entire bottom plate and essentially break the original assembly off the inlet before I could think about replacement.

Along the way I broke a wire saddle and the cosmetic cover on the hockey-puck like feet came unglued. I also discovered things I wish I had not known and could have probably lived happily not knowing about them. Alas, once seen I had to change things.

You can replace the inlet with a lot less effort than I did here. In case you must follow in my ill-advised path here is the disassembly instructions:

- Remove the bottom cover.

- Clip the wires at the white connector below the inlet. Do NOT clip them at the other end.

- Use a large flat heat screw driver and wedge it between the back of the IEC connector and the PCB, and twist firmly. You are pulling the pins out of the inlet by force.

- Unscrew the IEC connector from the back of the case.

- Pull the other end of the cable off the PCB. You may need to pull on the Molex latch a little. It's more of a friction fitting as opposed to a latch.